Having ink on your food probably doesn’t sound very appetizing, but many food products are coded or otherwise directly marked, for production, packaging, or resale. Food manufacturers and resellers are typically required to use food grade or human consumption ink for these markings. If you’re considering manufacturing or reselling any food product, note some important information about food grade ink and how it can benefit your business.

How is food grade ink different

Human consumption ink is typically made with soy or other food substances as a base. Food grade inks also have strict handling and storage requirements, so that the ink is not contaminated and doesn’t break down before use.

Many human consumption inks are also drier than standard inks so that they don’t get absorbed or seep into a food product. This dryness also keeps the ink stable when exposed to moist products, such as meat.

Contact between a printer and a food product can damage foodstuffs, so these products are usually stamped or marked with a continuous inkjet printer (CIJ), which sprays ink rather than rolling it onto a product. CIJ printers are very precise so that they can print barcodes, warning symbols, inventory numbers, and the like on even the smallest of food items.

When food grade ink is used

Food grade ink is often used in slaughterhouses and processing plants, where large slabs of meat are usually stored without outside wrapping. Codes that denote the meat’s expiration date, place of origin, arrival date, and so on are often put right on the meat itself.

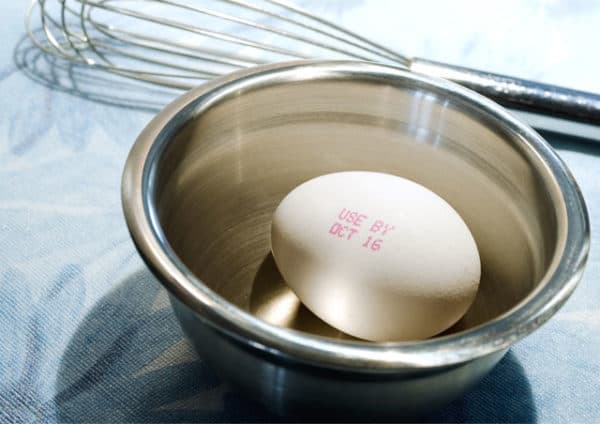

Some food printing remains even to the point of resale; for example, messages on candy hearts or symbols on medical pills are printed with human consumption ink. Food grade ink is required even if the part of the food to be stamped is typically discarded, such as orange peels and egg shells.

Food grade ink is also often legally required for utensils, tools, and other items that come into contact with food. For example, popsicle sticks and chopsticks are typically required to be printed with food grade ink.

Packaging that comes into contact with food may also need to be printed with food grade ink. This packaging might include bread wrappers, egg cartons, and single-serve wrappers for candy or chips. Labels that are put directly onto food products may also need to be printed with human consumption ink.

Benefits of food grade ink

One benefit of using food-grade ink is that you can print information directly onto a product, saving you both time and money on unnecessary packaging. Using food grade ink can also allow you to sell individual items more efficiently, such as produce. When you use food-grade ink to mark different pieces of fruit and vegetables, you can sell those pieces by themselves, rather than having to bag them up and label the bag or box with expiration dates, vendor codes, and the like.

The drier consistency of food grade inks also makes them an excellent choice for humid environments or for products that would otherwise absorb ink, such as cloth fabrics, rugs, and the like. Since human consumption inks are non-toxic and made with biodegradable materials, they’re also safer for the environment. These inks won’t seep contaminants into the soil or groundwater as a package or discarded foodstuff degrades and breaks down.

All of these benefits make food grade or human consumption ink an excellent choice for just about any application, beyond the food and beverage industry. If you’re looking for a nontoxic, environmentally safe, and very durable and stable ink for your product or packaging, consider the use of food grade or human consumption ink.

Gearfuse Technology, Science, Culture & More

Gearfuse Technology, Science, Culture & More