Logistics is the backbone of the global economy. No matter the industry, businesses depend on supply chains or impeccable transportation: stores deliver goods, tourist agencies cooperate with transporters, and so on. So, each process must be well-oiled. But there are always risks of potential disruptions and delays, risks that something might go wrong. And businesses must consider this well in advance—taking proactive measures is much easier than eliminating damage.

And, thankfully, tools for such measures are already in abundance—technology doesn’t stand still. Logistics management software companies build digital solutions that help businesses detect risks, predict disruptions, and carry out other important tasks. So, now you can easily detect risks before problems become tangible. And this awareness allows you to act—here and now, not waiting for a problem to emerge.

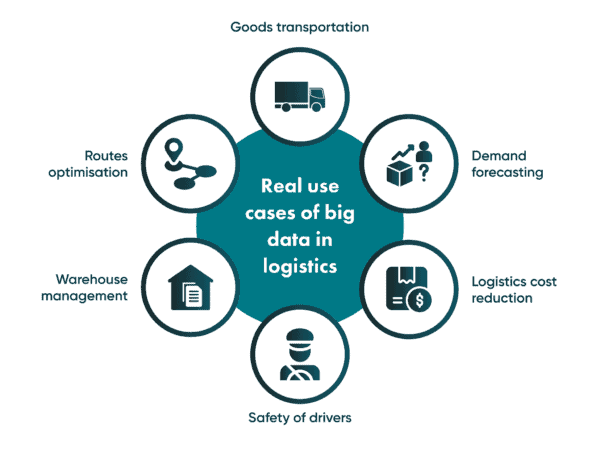

Mostly, modern software of this kind depends on data analytics in logistics. Big data in logistics is the major focus of this piece; let’s find out how it enhances monitoring and decision-making.

Big Data in Logistics: Managing Modern Supply Chains

Logistics operations generate vast amounts of data daily. No wonder—supply chains are getting increasingly complex and globalized. Any specialist, any organization willing to manage them successfully must therefore regard big data in logistics as a top priority. Analytics is indispensable, and you must be aware of how innovative tools help you get valuable insights, and, what’s more, use them profitably. It’s all about collecting and analyzing massive datasets. This is not easy, but if you succeed, you’ll benefit from impeccable visibility, which, in turn, will help you make sound decisions.

Big data in logistics has its peculiarities, and you must fully realize what benefits it gives to use it in the best possible way. Volume is the first thing to be aware of. Logistics data is massive, and its volume is constantly growing. IoT sensors, transactions, and GPS tracking—these and other sources deliver data every day, non-stop. Diversity is another vital characteristic. Data comes from unstructured sources and varies across periods and geographies.

As you can see, everything is complex, but data analytics in logistics helps make sense of this complexity. For instance, businesses can use advanced algorithms to uncover hidden patterns or trace meaningful trends. It’s not just a vast database that you get and don’t understand how to handle. With data analytics in logistics, you obtain a critical benefit—a multidimensional, granular view of your operations. What’s more, now you can not only analyze what has happened to learn a lesson from a mistake but also predict what comes next to prevent such mistakes.

Big data in logistics is a life-saver for modern companies. It powers a transition from reactive to proactive management.

Big Data in Logistics for Agile Control and Management

Big data in logistics and innovative analytics tools are indispensable for a variety of reasons. We’ll focus on two vital aspects—monitoring and decision-making. These are relevant to almost any area of the entire industry. Actually, success here greatly depends on constant control and sound decisions. So, let’s plunge into this topic in more detail.

Predicting Disruptions Through Data Analysis

Rapid or at least timely operations are a must. There are too many industry players nowadays, so if you are slow, someone else will outpace you. Another company will gain over your audience. And a very realistic scenario when something like that can happen is a delivery delay.

So, you should pay attention to software with robust ML algorithms. They handle shipment tracking data to identify potential delivery delays. Their capacities are impressive—they consider factors like weather, traffic congestion, and vehicle breakdowns, and everything is processed in real time. Moreover, they calculate and update ETAs. With such functionality at hand, you can notify customers of expected delays and take corrective actions like rerouting.

For example, by combining real-time GPS location data with weather forecast APIs, logistics firms can predict areas likely to be impacted by heavy rain or snow. Shipments can be quickly rerouted away from these high-risk zones even before disruptions occur.

Another useful feature is sentiment analysis. Firms apply it for social media posts and news articles. This helps them identify emerging events like political unrest and labor strikes—these are far from being a rarity in today’s turbulent society. As a result, businesses can foresee potential disruptions and adapt plans to avoid impacted areas.

Predictive maintenance algorithms are applied to sensor data from fleet vehicles to minimize downtime. Based on telemetry data, they identify parts likely to fail soon. Transporters then schedule preventative maintenance or part replacements. This helps companies avoid unexpected vehicle breakdowns that lead to shipment delays.

Customs clearance delays are also a thing to consider. With data analytics in logistics, firms scrutinize historical clearance times, shipment data, customs agency workloads, and external information on new trade policies. And this process is rapid and seamless, which greatly enhances the efficiency of workloads. When transporters understand what bottlenecks might emerge, they can redirect shipments to other ports with more capacity. This allows businesses to avoid customs delays that in certain cases totally paralyze vital processes.

Streamlining Inventory and Orders Dynamically

Retailers are employing real-time POS and inventory data to improve stock levels dynamically. ML models accurately forecast demand, which helps human specialists make decisions concerning inventory and stock. As sales unfold, stock levels are adjusted in real time across warehouses and stores.

For instance, by processing real-time sales, inventory, and client data, retailers can accurately predict the best-selling items during holidays or promotions. Additional stock of fast-moving products can be routed to the right locations ahead of anticipated surges in demand. Slow-moving items are reallocated well in time before they accumulate carrying costs.

Accurate analytics secures complete visibility into inventory across the extended supply chain. Data from suppliers, contract manufacturers, logistics partners, and sales channels is aggregated into a common view. Retailers can use sales patterns to anticipate and handle potential stock shortages or surpluses. Inventory buffers are dynamically aligned to match demand.

Retailers also employ data analytics in logistics when working with past customer purchase data. This allows them to make accurate predictions and forecast stock requirements for product assortments tailored to local customer profiles. Store staff receive prompts to reorder items personalized for their shoppers. This is what one can call microtargeting of inventory—and it truly enhances service levels and sales.

Real-time order tracking data also enables dynamic order promising. eCommerce retailers can accurately promise delivery dates and times to customers based on actual fulfillment capacity. Smart algorithms help predict the influence of new orders on delivery timelines. Online shoppers receive personalized and reliable ETAs tailored to ongoing warehouse workloads.

By using accurate and relevant information, retailers dynamically match inventory to emerging demand patterns. This way, companies can reduce stockouts, write-offs, and inventory costs and at the same time improve their services. The agility to adjust stock at a particular moment rather than reacting after the fact secures intelligent, self-optimizing inventory systems.

Route Optimization and Asset Tracking

Routes are an integral part of logistics processes. And too often companies have to adjust and optimize them. Congestion, bad weather, accidents—there are many reasons why a company might need to optimize routes for its fleet or a separate vehicle. And this is easy and seamless with big data in logistics—GPS updates, traffic patterns, and weather-related information are at hand.

Logistic providers leverage smart algorithms to analyze past and current traffic data to identify the optimal delivery routes. As new data comes in, route recommendations are continuously updated to avoid emerging bottlenecks and road closures. Precision grows day by day—ML models constantly incorporate new data and thus offer much more accurate predictions.

Precise fleet tracking provides logistics managers with dynamic visibility into vehicle whereabouts. This allows dynamic scheduling and rerouting of vehicles to meet changing delivery timelines. GPS data helps optimize asset utilization by matching nearby idle trucks with new pickup requests.

Companies also use sensor data from fleet vehicles to optimize processes. Fuel consumption sensors identify trucks with dropping fuel economy. As a result, human specialists can schedule such vehicles for preventive maintenance before breakdowns occur. This helps companies avoid disruptions. Engine fault sensors predict potential failures, so parts can be replaced in time.

By combining routing algorithms with real-time asset tracking data, logistics providers can continuously optimize their operations. They adapt delivery routes to changing conditions and in this way improve turnaround times. Assets like vehicles are dynamically aligned to tasks to improve utilization rates and service levels. Advanced ML algorithms are applied to streams of logistics data to optimize dynamic delivery routing and asset utilization in real time.

By using historical data and real-time telemetry, AI continually optimizes routing and asset allocation. Logistics resources are intelligently aligned to tasks, reacting instantly to disruptions while predicting emerging issues before they occur. Advanced data analytics in logistics secures intelligent, self-optimizing logistics operations.

Enhancing Visibility and Coordination

Tracking shipments in real-time throughout the entire supply chain provides full visibility. Shippers can monitor flows across their external carrier network and react faster to delays. IoT items like GPS and RFID tags facilitate data capture.

Manufacturers gain a big picture of material flows by combining order, inventory, and shipment data from vendors, 3PLs, and internal systems. This connectivity secures visibility into potential component shortages or delays emerging anywhere in the network. Specialists can adjust production schedules to avoid manufacturing disruptions.

Retailers are also leveraging data to coordinate inventory holding across stores, distribution centers, and suppliers. By sharing POS, inventory, and order data across the extended network, inventory levels are dynamically aligned with real-time demand signals from stores. This omnichannel visibility smoothens fulfillment and reduces stockouts.

Blockchain also enhances supply chain transparency through distributed ledgers. All network partners can view and verify asset flows and transactions—and this substantially improves trust and coordination. Automated smart contracts trigger processes like payments and receipts based on shipment events.

Control towers provide enhanced visibility by integrating data across planning, logistics, and finance modules. They monitor KPIs and investigate disruptions, ensuring better cross-functional coordination. They enhance resilience through a single pane of glass into material flows.

Thanks to real-time data sharing among supply chain partners, siloed functions give way to collaborative, synchronized processes. Inventory is dynamically balanced with demand, supply shortages are anticipated earlier, and disruptions are addressed in proper time. This visibility and coordination optimization are prerequisites for intelligent and self-regulating supply networks.

Conclusion

As you see, big data in logistics is an issue that modern organizations cannot ignore. Business relationships are growing, and so are supply chains. The gigantic volume of accumulated data is something that no human expert can handle anymore. So, the solution to the problem is clear—advanced data analytics in logistics and relevant software tools to perform it most efficiently.

Gearfuse Technology, Science, Culture & More

Gearfuse Technology, Science, Culture & More