Few pieces of equipment in your shop are going to prove as durable as your coordinate measuring machine; its body experiences little wear and tearif you load and unload properly and it has not been transported, or was transported by experts. You still see instruments in use from the 1990s and you may even have one yourself, as they can be mechanically useful for as long as 35 years. However, even though the structures of the machines have changed very little over the decades, metrology manufacturers are always developing new technology and software to make the inspection process faster and more accurate.

A metrology dealer can help you retrofit and upgrade any well-maintained coordinate measuring machine to bring it up to contemporary standards, solving bottlenecks and providing your shop with a more competitive turnaround time. But there plenty of upgrade options available and it may not be immediately clear which ones will give you the most value and improve your competitive edge in 2016. Below are some of the smarter upgrades and retrofits recommended by metrology dealer Canadian Measurement Metrology, also known as CMM, which they regularly provide owners of older equipment and shops that buy used coordinate measuring machines.

Refurbishing

A dealer can refurbish the body of the equipment if it has worn out mechanically, further extending the lifespan of a significant investment. Good maintenance practices can help prevent your machine from wearing down, particularly cleaning exposed bearings and the slave leg, which frequently accumulates particles that can then damage the surface plate. To find out if the make and model you own is eligible for an upgrade or refurbish, visit www.cmmxyz.com and learn more about the kinds of upgrades you can make.

Software

The software you use likely needs to be upgraded more frequently than any other part of the equipmentin order to keep up with today’s demanding pace and standards, as OEMs are regularly making improvements to their software. One of the most widely used software programs is PC-DMIS, in part because it is compatible with non-OEM controllers and because it is easy to program from a CAD without having to wait for a part.

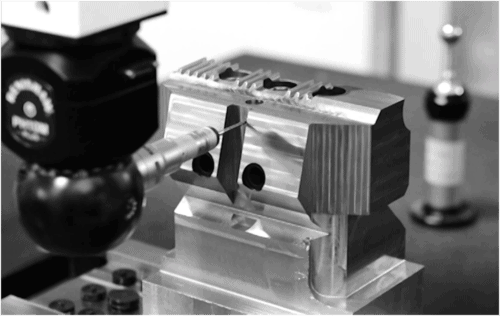

Probes

The probes you use define your coordinate measuring machine’s performance and you can save yourself time, retrieve more accurate data, and handle more complex workpieces with newer probing systems like the 5-axis Renishaw PH20, a touch trigger system that will improve your repeatability. It also minimises the space needed for head rotation, using infinite rotation and few stylus changes. Upgrading your probing system with retrofitters like CMM improves the two most important factors in coordinate measuring machine performance: accuracy and repeatability, not a technology to skip.

There are probably decades of use left in your older inspection equipment and you can save considerably by improving your inspection technology. Breathe new life into your coordinate measuring machine with the help of a reputable metrology retrofitter and bring your quality assurance techniques into 2016.

Gearfuse Technology, Science, Culture & More

Gearfuse Technology, Science, Culture & More